Occupational health and safety

Global management approach to occupational safety

NORMA Group has been pursuing a Group-wide approach to occupational health and safety by making improvements for years. Regular risk assessments at the production sites show that machinery and vehicle traffic are the most important factors here. Against the background of the systematic Group-wide approach to safety and health management, NORMA Group considers these risks to be low overall. Due to the high risk of injury, an important initiative launched in 2022 and continuing in 2023 at a global level is the introduction of automatic vehicle restraints and forklift dock guards to avoid the risk of potential catastrophic accidents at NORMA’s shipping and receiving docks. 73% of active NORMA Group loading docks are now protected with the engineering safety controls, including 98% of the sites in the Americas region and 44% in the Asia-Pacific region. In the EMEA region, 3% of active loading docks are secured with vehicle restraints, with further implementations planned in the upcoming months. However, the sites in the EMEA region that do not have vehicle restraints use either motorized or manual wheel chocks for safety control. These efforts will continue until all loading docks have been secured.

Laws and regulatory frameworks provide clearly defined standards for occupational health and safety at the company. Considering the subject’s importance, it is addressed in the OCCUPATIONAL HEALTH AND SAFETY POLICY, which is valid throughout the Group. In the policy, NORMA Group commits to providing a safe and risk-free working environment for all employees and any other stakeholders affected by its business activities. Through supplementary programs, the company aims to ensure that all workplaces offer the highest level of safety to avoid accidents and incidents. In particular, the site locations make technical arrangements and conduct training courses to prevent accidents at work. These high standards apply to temporary workers as well as to regular staff. As part of continuous efforts to improve the prevention of injuries/illnesses, a major NORMA Group initiative in 2023

6 Information on employees is generally provided in headcount for all active NORMA Group employees. This includes both full-time and part-time employees, but not trainees or interns. The figures are based on an annual average.

involved an eight-month project to implement a standardized method (application) for the “Safety Triangle Data” with a focus on injuries/illnesses and near misses. In the lower part of this triangle, reference is made to an additional application “Value-Based Safety (VBS) Observations”, which reports potentially unsafe behaviors or unsafe conditions that lead to potential risks or safety hazards.

Certification of all manufacturing sites

Throughout NORMA Group, all manufacturing sites have local health and safety representatives, who – along with the respective plant management and safety committees – ensure the implementation of health and safety standards and serve as experts for questions on the topic. At the end of December 2023, 23 of the 25 production sites were externally audited and certified in accordance with ISO 45001.

ISO 45001 prescribes conducting regular assessments at site level to identify risks for the occupational health and safety of workers. On this basis, regular internal audits are carried out to identify potential for improvements and to define appropriate measures. Progress resulting from these measures is tracked regularly. NORMA Group leverages the development of the OHS to sustain safety performance. In addition, NORMA Group also includes health and safety certifications in its supplier scoring process. SUSTAINABILITY IN PURCHASING

Health and safety governance on the global, regional and local levels

The success of NORMA Group’s health and safety management is assessed by regular reporting by the global health and safety management team to the Management Board. Root cause analyses are derived from this at the site level, and countermeasures are defined. Progress on systemic measures is also reported to the Management Board.

In addition to regular EH&S regional staff meetings, the regions have the option to conduct a Health and Safety Circle meeting that requires its applicable locations to conduct self-assessments on the current status quo of their health and safety activities and strategic initiatives. Participants include the health and safety managers or representatives of each location in the respective region as well as the regional and global health and safety management team. Usually, the circles also invite participants from other regions to increase the sharing of best practices on a global level.

Accident rate as key performance indicator

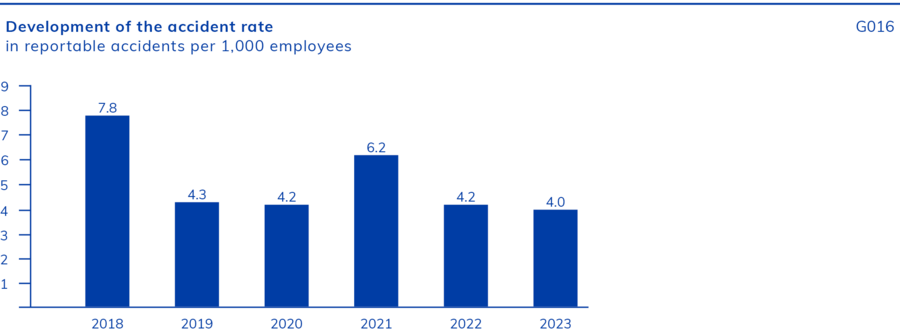

Introducing management systems for occupational safety is not an end in itself. To monitor their effectiveness, NORMA Group monitors the accident rate, which counts the number of accidents per 1,000 employees that result in a loss of work of more than three working days. In 2023, the accident rate per 1,000 employees was 4.0, which means a decrease of 4.8% compared to the previous year (2022: 4.2).

A new systemic improvement measure introduced in early 2022 and continued in 2023 to reduce the accident rate is the launch of the Safety Top Focus program, which includes risk monitoring and controls as well as leading and lagging OHS indicators with oversight for key manufacturing sites that fail to meet accident rate targets. Top management is responsible for oversight in this regard. The program’s focus in 2023 was on improvement measures for high-risk areas and upgrading the relevant facilities with appropriate safety controls in order to fully optimize occupational health and safety standards. In addition, the fundaments of the OHS management system (e.g. safety audits focused on identifying potential safety risks) were further developed. Each site participating in this program prepares a monthly report, which is sent from the plant manager to top management.

As in previous years, there were no fatalities. The goal is to further reduce the accident rate in the coming years. However, as 2024 is a transition year for the introduction of new health and safety indicators based on the CSRD requirements, the target of reportable accidents per 1,000 employees per year remains the same as the previous year at 4.35. CR TARGETS

The calculation of the accident rate and number of medical treatments is based on the total workforce including temporary workers.

NORMA Group also monitors the number of medical treatments or accidents that result in a work loss of less than three days (medical treatment rate). In 2023, this figure stood at 23.1 treatments per 1,000 employees. The rate increased slightly compared to 2022 (21.3 treatments). The main reason for the 8.5% increase in the Medical Treatment Incident Rate for Group level in 2023 compared to the previous year is due to a 31% increase in the medical treatment cases in the Asia-Pacific region and 8.3% increase in the Americas region. The EMEA region remained unchanged compared to the previous year with a 1% decrease. The APAC region experienced a 78% increase in the number of medical treatment cases. The main reason for the increase in the region was the sharp rise in treatments at Kimplas Piping Systems Ltd., while the increase in the Americas region was attributable to the sites operated by Craig Assembly, R.G. Ray Corporation and NORMA Pennsylvania Inc.

In order to focus on preventive rather than reactive measures, NORMA Group also monitors the number of “near miss” events, which are occasions where an accident nearly happened but was just avoided. Incidents, medical treatments and near misses are reported to line managers, who report this information to local health and safety representatives.

Legend

These contents are part of the Non-financial Group Report and were subject to a separate limited assurance examination.